Review

In part 1 of this three-part series, we discussed that there are operational costs when the right part isn’t at the right place at the right time. Expedited transportation, technician lost productivity, and equipment downtime cost are key examples of stockout costs that can occur when a service call cannot be closed immediately due to a missing part.

In part 2 of this series, we introduced the costs of inventory and plan instability. Inventory costs money, and more inventory (at least more of the right inventory) can buy a better service level. There are also operational costs if a planning system isn’t biased to plan stability. Plan changes incur transportation and logistics charges, as well as personnel time to manage the changes.

In this final part of our exploration of Total Cost Optimization, we bring these operational and inventory costs together to show that service level is better viewed as an output of an optimization rather than as a goal, as the right service level minimizes the combination of these costs.

Inventory Costs vs. Stockout Costs

Understanding stockout costs incurred when a part is unavailable is quite easy at the extremes of inventory stocking.

- If you carry zero inventory, every demand that occurs will result in a stockout, and each demand incurs all the operational and expediting costs associated with a stockout.

- If you hold excessive levels of inventory, then stockout probability approaches zero and the corresponding likelihood of incurring any stockout costs approaches zero.

Between these two extremes, as inventory is added, stockout cost risk is reduced. The key to true organizational cost optimization is to find the point where adding additional inventory starts adding more inventory costs than the corresponding stockout cost risk reduction enabled by the additional inventory.

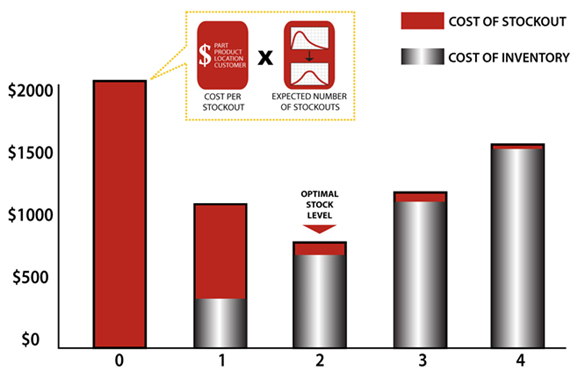

The chart above shows a hypothetical cost optimization example. In particular, it shows how stockout cost risk is reduced as inventory is added, but inventory costs increase. There are no inventory costs at a zero-inventory level, and stockout costs are reduced to near zero at higher inventory levels.

In the above example, stocking a level of one is projected to reduce the number of stockouts by more than half, so the expected stockout costs decrease accordingly. Adding inventory incurs costs, but the reductions in stockout costs is significantly more than the added inventory cost, an inventory level of one is a lower total cost than zero.

Adding another part, to bring the stocking to a level of two, causes another large decrease in stockout costs, and a roughly linear increase in inventory costs. At this point, the stockout risk becomes very small, so small that any additional inventory added can’t reduce enough additional stockout cost to counter-balance the added inventory expense.

As the lowest total cost option, a stock level of two is the optimal stocking position for this part at this location.

What About Service Level?

Most inventory planning systems target a specified service level goal. In cost optimization, service level is an output of the process at the lowest cost point, rather than the target of the optimization.

The problem with service level goals is that they’re often arbitrarily defined. If your company is targeting a ninety-five percent service level, you need to ask, “Why is ninety-five percent the target?” The likely answer is that it was found to be a convenient point where it felt like inventory costs and stockout costs were balanced. It was an arbitrarily set goal that felt right, which isn’t a true optimization.

In fact, some organizations create complex, overlapping service level goals for categories of parts using ABC classifications and other groupings, which can be very hard to manage effectively and can cause inventory churn. The downsides of using ABC stratification for optimization will be a future article.

Sometimes, due to contractual commitments, a minimum service level goal is necessary, even if it moves the inventory target to a non-cost-optimized state. Targeting a specific service level goal should be viewed as a constraint on an optimized state, rather than the core optimization.

Inventory Stability

A key benefit of cost optimization is that it allows for easy identification of situations where changing a stocking target from one level to another doesn’t provide a cost justification. For example, if your optimized target moves from one to two, but the optimization result is close enough that the cost benefit of changing the stocking level does not exceed the operational costs of changing the stock level, then the planning system can be intelligent about leaving the stocking target at one. This biases the system to the current state, reducing churn and further reducing operational costs.

Summary

A planning system that only allows its users to identify service level goals is not truly optimized. Optimization is only achieved when the minimum of total operational costs of inventory investment plus stockout costs are at their lowest possible level.

Only a planning system that offers cost optimization can provide this lowest total cost approach to stock levels. This, combined with understanding the operational costs of changing a target stock level, means BaxterProphet is your best solution for Service Parts Planning. Ready to learn more about our Service Parts Planning Software? Contact us today!