Optimize Multi-Echelon Inventory

SUMMARY

Balancing inventory budgets and service levels is a common challenge in supply chain management. Field engineers and demand more inventory to meet aggressive service level agreements. Supply chain and financial teams struggle with reduced profitability from escalating service inventory and write-offs.

The pace of new products being introduced is increasing in many industries. Without optimization, obsolete inventory accumulates and can cause delays in making the latest generation of parts available to the market.

The problem is accentuated when the hidden costs of unavailable inventory such as service penalties, expedited shipping costs and lower customer satisfaction are considered. The impact of these unplanned expenses on service organization profits is significant. Baxter Planning’s unique planning functionality considers all of these variables and delivers optimization solutions driven by the total cost of the service supply chain.

Find out for yourself how Baxter can optimize your service supply chain inventory.

Complete this form and we’ll get in contact with you or email us at info@baxterplanning.com / call us at +1 (512) 323 5959 .

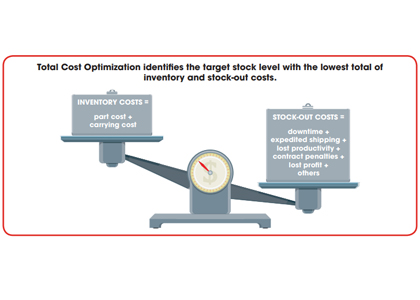

Total Cost Optimization

Inventory planning solutions often begin the optimization process using an arbitrary service level target as the goal. While these models prove valuable for just-in-time manufacturing planning, they do not provide a cost optimized solution for the just-in-case requirements associated with service supply chains.

Baxter’s total cost optimization solution models qualitative and quantitative cost elements to determine optimal target stock levels that yield optimized service levels. By including the cost of a “stock-out” in the calculation, the system achieves levels of optimization only possible with a solution designed for service parts planning.

Stock-out costs occur when the required part is not available at the ideal location. Stock-out costs are derived from factors that include customer importance, downtime costs, service contract penalties, expedited shipping fees, lost technician productivity, and lost profit, among other expenses. With Total Cost Optimization, the optimal target stock level is the one with the lowest total costs of combined inventory and stock-out costs.

Operational Service Level

A key component of Total Cost

Optimization planning is the ability to differentiate between theoretical service level and operational service level. The theoretical service level metric commonly employed measures only whether the inventory to meet demand was anywhere in the service provider’s supply chain. This measure ignores the additional service supply chain costs cited. Even though the reported customer service level metric may be accurate, the cost of providing this level of service often includes hidden costs. Operational service level is the supply chain’s ability to not only fill the demand, but to fill it on time from the most efficient site in the network.

To enable continuous improvement, Prophet determines the actual optimized fill rate using Total Cost Optimization. When a material demand is not filled from the optimal (planned) site, Prophet’s root cause analysis determines if the “miss” was a result of supplier problem, transportation delays, data issues or a variety of other potential problems. This automated analysis of non-optimal fulfillment allows the planning organizations to identify key issues and implement supply chain-wide corrective action.

Results

The results of adapting the Total Cost Optimization planning model are dramatic. Baxter has enabled clients of all sizes – from small companies with revenues of just a few million dollars to Fortune 500 enterprises – to reduce inventories by up to 50% while simultaneously improving service levels to better than 99%. Contact Baxter Planning to learn how to improve the bottom line without risking customer satisfaction through Total Cost Optimization.