Inventory Planning & Service Execution: Part One

The Hidden Miss in Your Field Service Optimization Plan

Each link in your service organization strives to achieve a common goal: meet customer service level agreements (SLA) at a reasonable and predictable cost. But too often, businesses’ sub-operations fail to dance in sync, even if they’re well-choreographed on their own. This two-part blog series addresses the common pitfall of having disparate Service Parts Planning (SPP) and Service Execution (SE) logic. Part one looks at some easy-to-miss examples of disharmonic SPP and SE. Part two explains how to uncover the root causes of hidden inefficiencies and how to improve them.

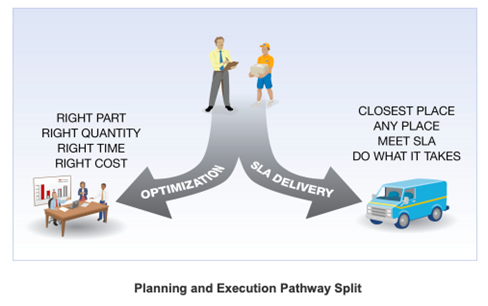

For most organizations, SPP includes four main steps: planning a logistics network, forecasting supply and demand, optimizing inventory, and generating orders to maintain ideal inventory levels. It’s a proactive, back-office process that ensures you’ll have the parts you need to meet customer demands.

SE is the front-office, client-facing process that controls the actual delivery of service. It includes selecting the optimal part from the best location to fulfill each service call or request for a service part. In contrast to SPP, SE is a real-time, day-to-day activity.

You may have spent considerable time calculating exactly how many parts to stock in each location and invested in the best technicians to meet delivery expectations. But if you’re like most companies, your seemingly ideal SPP and SE operations aren’t yielding the customer satisfaction or bottom-line growth you want. That could be because they fail to share a common set of logic, as the pathway towards their common goal often splits.

On paper, the gap between SPP and SE may seem like an obvious one to bridge, but that’s not the case in practice. Let’s look at the complexities that comprise each element.

Service Parts Optimization

The nature of SPP varies across organizations.

- One company may provide direct onsite support and know exactly where all their parts are installed, as well as the SLA associated with each client or piece of equipment.

- Another may sell and service products indirectly via a distributor without visibility to customers or installation sites.

- Product and parts life cycles and support requirements range from months to decades.

- Logistics networks can consist of one central warehouse, regional warehouses, or a global network of thousands of locations.

- Purchase and repair suppliers may be centralized or local to various regions.

A fully optimized planning system also needs to consider the criticality of location and customer, inventory cost, emergency transportation cost, replenishment cost, and other internal or external costs driven by a service part request failure (“stock-out costs”). Stock-out cost examples include the cost of a repeat visit by a technician, a service contract penalty clause, or expedited transportation fees.

Service Execution

Service Execution (SE) typically includes a call center, dispatch, parts sourcing, reverse logistics, and repair processes. A key goal of SE is to meet customer SLAs, whether it involves a next-day part shipment from a central warehouse or two-hour support from one of thousands of field engineers. That said, a number of issues might arise around each component of every service call, including:

- Contractual or management-driven SLAs

- Part chaining: the process in which one part can substitute for another

- Cross-border shipping considerations, which must account for each country’s rules, regulations, and customs requirements

- Warehouse hours of operation across time zones

- Shipping cut off times, which can vary by stocking location and time zone

Of course, while SE is measured on its ability to meet customer service level commitments, managing related execution costs is equally critical.

When you consider how much work goes into optimizing SPE and SE, it becomes clear how some firms focus so heavily on each operation that they forget to synchronize them. Unfortunately, the missing link often ends up degrading both operations.

A Common Example of the SPE and SE Split

A California high-tech company understood the interchangeability of old and new parts and would only stock an optimal amount of the combined quantities. Here’s where things fell apart for them:

- Service calls resulted in requests for one version of the part, but the operational system didn’t register that they could get another equivalent part locally.

- The company often expedited the exact part number from a sub-optimal location, paying premium freight charges to meet time constraints.

- When they couldn’t automatically get the part they needed, only then did they enlist a technical expert to find another, usually more accessible, part. (If they had baked this step into their standard process, they would’ve been more likely to source parts from the optimal location to begin with. Instead, as a rushed, ad hoc measure, it accrued unnecessary expenses.)

Despite the miscommunication issues and inefficiencies across their operations, this company carried on with a false sense of accomplishment for a while. Why? Because of the way they interpreted their data. Since they were generally able to get each desired part to their customers on time, they marked their “success rate” at ninety-three percent. This number misled them because it weighted the success of each on-time delivery the same, regardless of how much extra they spent on freight or time they lost to inefficiencies.

Eventually, the firm saw the cracks in their processes and their true hit rate came to light, now at seventy-six percent. This rate reflected only the cases where they had sourced the part from their planned stocking locations. After installing tools to help correctly identify alternate parts, the hit rate jumped to eighty-five percent. Then, with the introduction of root-cause reporting for their misses, they were able to fine-tune their planning and logistics models, yielding an accurate hit rate of ninety-six percent.

The case of this California firm isn’t uncommon, as it’s easy to misinterpret hit rates without the proper analytics tools. That point brings us to the second part of this blog series. Read it here for insight on how to construct proper data analysis for a crystal-clear depiction of your performance, as well as how to uncover the root causes of inefficiencies and breakdowns, plus how to fix them.

John P. Peterson III, CPIM

Enterprise Solutions Consultant

John is a supply chain professional with more than 30 years of experience; 25 years focused on the service supply chain. In 20 years at Baxter Planning, he has leveraged his expertise and experience to drive Implementations, Consulting, and Planning engagements.

In his current Enterprise Solutions Consultant role, John serves as a subject matter expert providing technical demonstrations and solutions development in support of our sales team. He continues to do extensive work on independent inventory analysis projects, to date identifying over $1B in inventory optimization opportunity alongside the opportunity to reduce service misses due to inventory shortages by over 30%. In 2019, John was named as a Supply Chain “Pro to Know” by Supply Chain & Demand Executive magazine.

Certified in Planning and Inventory Management by ASCM (formerly APICS), The Association for Supply Chain Management, John has served on the Board of the Dallas and Austin, Texas ASCM (formerly APICS) chapters.

John lives in the Austin, Texas area with his wife, Lisa, with whom he has twin sons. He enjoys spending downtime motorcycling through the Texas Hill Country, drumming, and ‘glamping’ around Texas.