Accurate Demand Forecasting Software for Service Supply Chain Performance

A fundamental requirement of supply chain management is accurate demand forecasting software. Overforecasting results in excess inventory and associated warehousing and obsolescence costs while underforecasting results in negative impacts to the end customer with missed SLAs (service level agreements). Supply chain excellence often starts with robust forecasting practices that master the art of matching supply with the help of demand planning software.

Demand forecasting methods for service supply chain are distinct from the production supply chain in several ways and is a shift in paradigm from “just in time” inventory to “just in case” inventory. The after-market supply chain forecasts for lower demand volumes and analyzes more sporadic demand patterns for older material that is often out of production. Service supply chains often experience intermittent demand marked by periods of zero movement, and traditional forecasting methods are not adept at comprehending these seemingly sporadic patterns and lack of structure.

Additionally, the service supply chain must account for reverse logistics and core repair considerations while forecasting across a complex network, from distribution centers to fields stocking locations, all the way down to a technician’s trunk stock. A strong forecast allows for accurate projections to suppliers and proper reporting of purchase and repair budgets. Forecasts are a key part of any target stock level calculation thus the accuracy of the target stock level, as well as the projected service level, have dependencies on the forecast. Confidence in the forecast will lead to efficiency gains with automated replenishment, automated redeployment, and automated supply orders which ultimately lead to improvements in service level and inventory optimization.

Find out for yourself how Baxter can optimize your service supply chain inventory.

Complete this form and we’ll get in contact with you or email us at info@baxterplanning.com / call us at +1 (512) 323 5959 .

Demand Forecasting Methods with Prophet Software

Best practice forecasting starts with the configuration of suitable forecasting methods and continues with consistent review and resolution of Forecast Alerts.

Forecast Methods

For time-phased models that bring in supply from outside vendors, the best practice is to use Installed Base or Auto-Select of statistical forecast methods.

- The Installed Base Demand forecast method calculates demand forecasts based on an estimate of month-to-month changes to contracts. Installed Base forecasting provides more accurate predictions because it is based on historical and current contract data while also capturing future contracts to allow for proactive planning of expected increases or decreases. Further, this method is better equipped to adjust to demand spikes and enhances the lifecycle management of materials.

- The Auto-Select method uses an algorithm to determine the statistical equation that best fits the historical data and considers forecasting methods such as Simple Moving Average, Croston’s Intermittent Demand, Automatic Exponential Smoothing, and BoxJenkins. Forecasting with Auto-Select is highly configurable, allowing customers to set specific parameters within the methods such as default number of historical months or outlier corrections settings that smooth spikes and dips.

For re-order point models setting optimal target stock levels at field sites, best practice is to employ rate-based methods to use the number of contracts and calculated demand rates to determine the forecast. With rate-based forecasting, projected demand is based on the number of contracts and the average number of occurrences per contract in either a single region or globally. Additionally, Prophet has developed forecasting tools specific to technician planning that allows an aggregate forecast at a team level to be allocated to individual technicians on that team. Technician forecast allocation distributes forecast to preferred technicians based on training, current inventory, forecast, and demand history of previous service calls to improve min stability and allocate forecast to the best fit technicians.

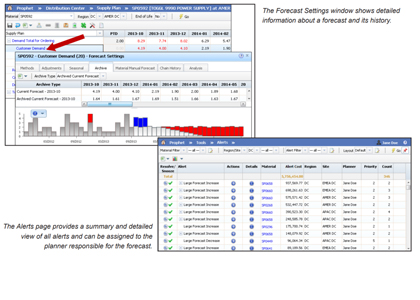

Inventory Forecasting Alerts

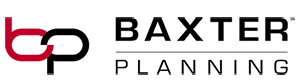

Once an appropriate forecasting method has been configured, Forecast Alerts allow planners to manage by exception so that data falling outside of pre-defined limits generates an alert for the designated planner. Forecast Alerts measure large deviations from an archived set of benchmark forecasts and alert parameters and thresholds are adjustable to match criteria unique to the customer’s environment. For planners that manage hundreds or thousands of products and materials, alerts help organize and prioritize planning activities.

Planning and Forecasting Solutions with Baxter

Baxter’s Best Practice Scorecard exemplifies a commitment to helping customers optimize and automate their service supply chains. Baxter has leveraged decades of experience to design, identify, and measure 30 critical service supply chain Best Practice categories during each client’s business review process. The scorecard is organized by practice area and the benchmarks for the Forecasting practice area measure whether the customer is utilizing the appropriate forecast method and performing timely reviews of Forecast Alerts. The results from the Best Practice analysis are used to identify and recommend specific opportunities for improvement while ongoing business reviews are designed to monitor the adoption of these recommendations.

Baxter offers a Forecasting Consulting engagement for Prophet customers to recommend appropriate forecasting methods that align with best practices. Depending on current data integrity and specific supply chain goals, Baxter experts will work with the customer team to review available forecasting methods and associated parameters as well as work to provide supporting data to facilitate the evaluation of the updates. A comparison of current forecast to newly modeled forecast makes it easy for the customer team to fully comprehend the effects of the updated forecasting while reports with different levels of granularity allow the customer team to evaluate the impact to target stock levels, order/replenishment suggestions, and service levels. Baxter’s Forecasting Consulting provides the customer team with a full understanding of best practicing forecasting methods and confidence in any forecasting changes’ impact to their service supply chain.

The Benefits of Utilizing Forecasting Best Practices

Forecasts are what ultimately drive target stocking levels, purchase/repair orders, and replenishment suggestions downstream in the supply chain. Improved forecasting will allow your organization to accurately communicate with suppliers and achieve high service levels while preventing excess creation. Adopting Baxter’s forecasting best practices are a key first step to achieving supply chain excellence.