Replenishment and Redeployment for the Service Supply Chain using Prophet Software

The service supply chain is met with unique challenges, but spare parts optimization presents a unique opportunity to reduce costs while increasing customer satisfaction. Spare parts planning is tasked with balancing field service inventory across a network of distribution centers, fields sites, all the way down to a technician’s trunk stock. Additionally, the after-market sector is tasked with forecasting intermittent demand for low volume, high mix materials while comprehending part-chaining requirements. Inventory Planning in a global critical inventory logistics network requires strategically balancing service level goals with inventory costs while continually managing excess and meeting the contractual obligations of rapid-response customer Service Level Agreements (SLAs).

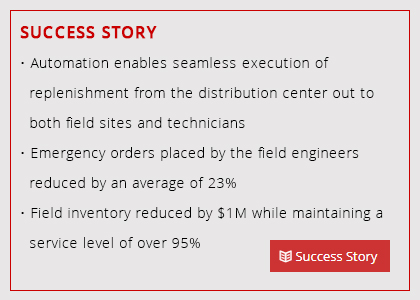

In other words, proper replenishment and redeployment practices are crucial to optimizing inventory across a complex network to ensure spare parts management organizations deliver on the service promise. The theoretical success of a service supply chain begins with an optimized plan but measurable, real-world results depend on an automated replenishment and redeployment process that understands current network conditions and requirements.

Find out for yourself how Baxter can optimize your service supply chain inventory.

Complete this form and we’ll get in contact with you or email us at info@baxterplanning.com / call us at +1 (512) 323 5959 .

Prophet’s Inventory Replenishment Software Capabilities for Service Parts Planning

Prophet by Baxter is a software as a service (SaaS) focused on field service inventory planning and execution to optimize service parts management operations. The Prophet service parts management solution enables the automation of Replenishment and Redeployment eliminating the need for manual intervention. If target stock levels are calculated to expectation, minimal interference is required for Prophet to stock field service inventory throughout a customer’s network of sites. Prophet’s redeployment replenishment capabilities drive improved decision making and enable process automation when balancing inventory across the network:

- When a limited number of replenishment materials are available, the Prophet replenishment calculation fills the most critical shortages first. This approach leads to higher service levels and greater customer satisfaction than the “fair share” method, which attempts to distribute the available inventory evenly across all shortage sites. Prophet prioritizes shortages based on the Backlog Criticality Index (BCI), which is the potential savings associated with avoiding the cost of stockout by replenishing an additional item to the current inventory.

- Configuration settings allow customers to decide whether replenishment orders are based on shortage quantity to reduce overall inventory levels or if those orders should be incremented up to an optimized economic order quantity to lower freight costs. Additionally, the system considers part-chaining by aggregating the on-hand balances of all inventory in the chained supersession relationship and with sourcing logic that prioritizes shipments of alternate materials, master materials, and new materials. Further, Prophet’s algorithm intelligently decides when it’s more cost effective to let a surplus in a local stocking location burn down locally instead of redeploying which saves money on unnecessary transportation.

- An intuitive interface allows users to designate sourcing rules that specify how items are balanced throughout the network. These rules define rebalancing relationships between sites, prioritize redeployment to redistribute excess before replenishing, establish desired ship days, and select preferred shipping companies and shipping methods.

- Automation of tactical activities allows planners to focus their attention on strategic initiatives most important to the business. Prophet’s configurable out-of-tolerance conditions will halt replenishment orders and alert planner of exception situations requiring review. Additionally, users can easily set exclusions to halt replenishment or redeployment at the material or site level in the case of site closures, material quality issues, holiday schedules, etc.

Service Parts Planning Analytics with Replenishment Software

Baxter has leveraged decades of service parts planning experience to design, identify, and measure 30 critical service supply chain Best Practice categories during each client’s business review process. This criteria is standardized in a Best Practice Scorecard and provides a foundation to deliver on our commitment to helping customers optimize and automate their service supply chains. The scorecard is organized by practice area and the benchmarks for the Replenishment and Redeployment practice area measure the customer’s automation capabilities, data integrity, and fill rate metrics as key indicators that the inventory plan is being executed successfully and efficiently.

Baxter advocates the adoption of best practices for automated and intelligent inventory movement throughout the supply chain network during the implementation phase, and continues to monitor adoption of these best practices as part of our ongoing support. With a myriad of customization configuration options for replenishment and redeployment available, the Baxter team works to understand the customer’s unique goals and then leverages Prophet’s capabilities to meet specific objectives. Baxter experts will review the current logistics network configuration, excess deployment objectives, warehouse volume constraints, the costs associated with expedites, and IT capabilities for data transmission. With that information, Baxter experts will customize a Prophet configuration that is automated and can be executed to achieve service level and inventory cost objectives.

For customers that are looking for additional support, Baxter’s Planning as a Service offering can provide an extension to your planning organization to perform these responsibilities. Your designated Baxter planners will perform a range of tactical and strategic initiatives including a regular review of the fill rate metric, analysis of sites with highest shortages and excess, reviewing replenishment exclusions, and ensuring valid chaining data.

The Benefits of Replenishment and Redeployment Forecasting Software

Automated replenishment from Distribution Centers to Forward Stocking Locations (FSLs) provides increased accuracy and efficiency and is essential to achieving an industry standard fill rate of 98%. Redeploying inventory between FSLs reduces excess inventory by using available to fill shortages and prevents unnecessary inventory purchases while ensuring that inventory is available to meet expected response times. Benefits from utilizing Replenishment and Redeployment best practice include:

- A reduction in next flight out (NFO) and overnight expedited shipment expenses as a result of an improved inventory availability throughout the service supply chain

- Cost avoidance savings driven by redeployment of current excess to fill target stock levels and decrease total inventory cost

- Increased planner efficiency with the automation of replenishment and redeployment processes